La Trobe University is pleased to announce a new initiative designed to increase the employability of our students.

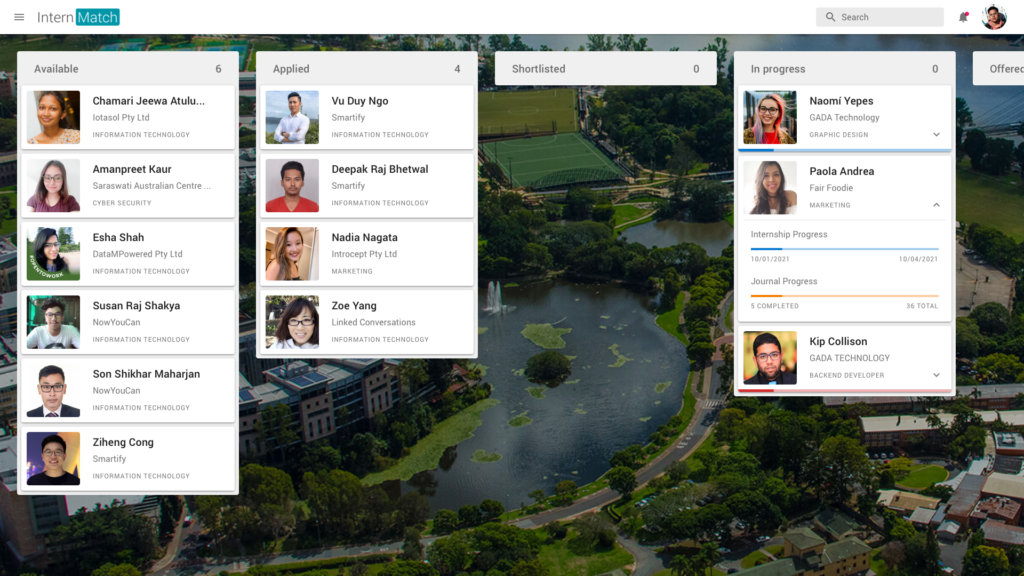

Launching in February 2022, we have entered into an agreement with Outcome.Life & InternMatch – a global internship management company – to assist us to place and manage our students into internships across Australia.

A primary reason, students come to La Trobe University to launch or advance their careers. In an increasingly competitive jobs market, success requires not only technical knowledge and skills, but also real-world practical experience. Accordingly, we have engaged InternMatch and secured IERF funding to help ensure our students get the experience necessary to be at the forefront when it comes to post-graduation employment.